Woody wrote:

They should be able to find a cheap, rust-free section of replacement bridge on Atlanta Craigslist. And they're lucky because they won't even have to trek down to Atlanta to get it.

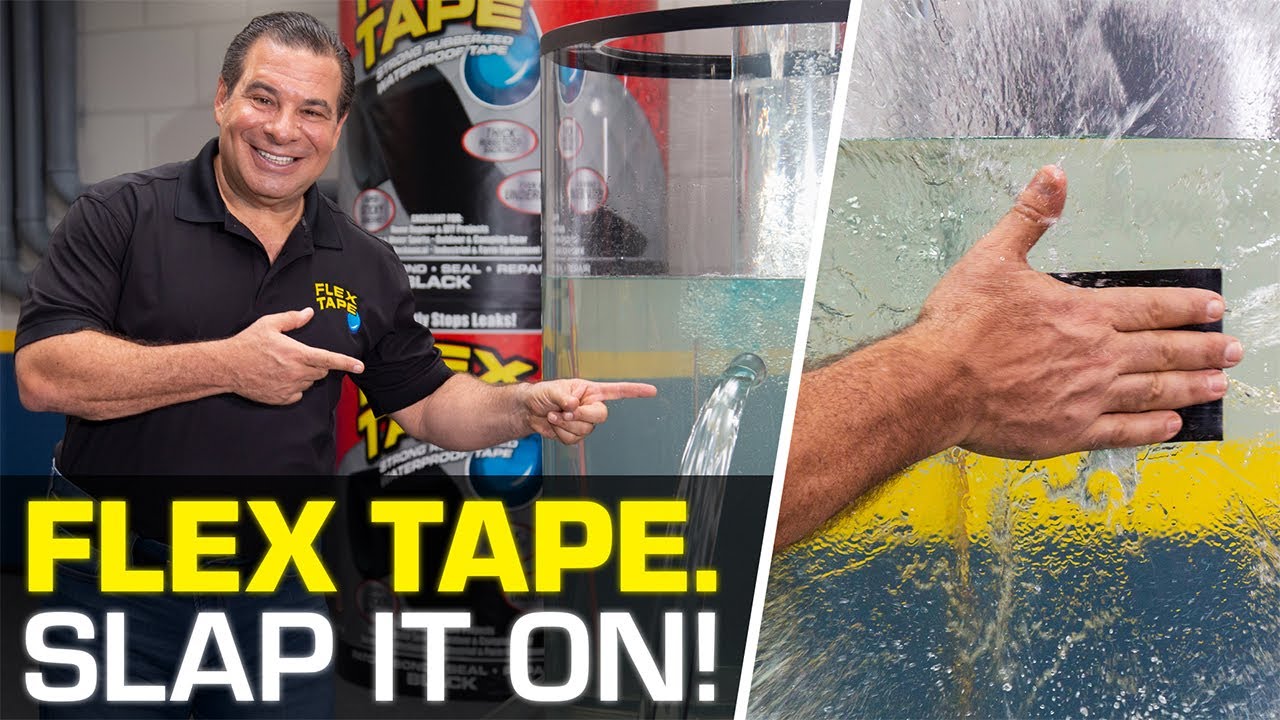

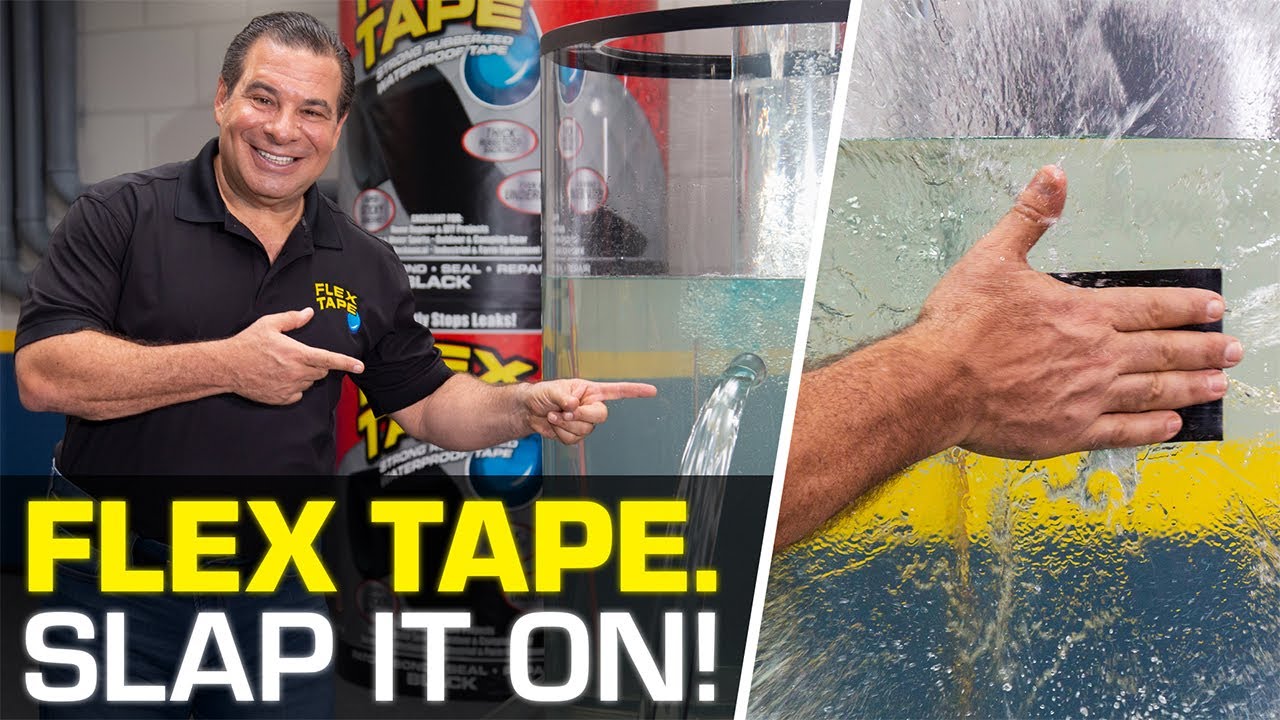

Actually, latest report I heard is that they're contemplating using this stuff...

Luckily I don't have much of any reason to go downtown for the next couple months. They're currently trying to assess the damage and figure out how much of the adjacent parts of the road are still sound so they can rebuild, but the fire isn't even completely out yet.

At least it appears nobody was injured.

Who would have guessed a large pile of pipe would catch fire and take out a bridge. How soon until the "Concrete doesn't burn people" decide this is some sort of conspiracy.

RossD

UltimaDork

3/31/17 7:36 a.m.

In reply to Wall-e:

The pipes were filled with jet fuel, duh.

(In before the lock!)

Brian

MegaDork

3/31/17 7:43 a.m.

RossD wrote:

In reply to Wall-e:

The pipes were filled with jet fuel, duh.

(In before the lock!)

But jet fuel can't melt steel, let alone do anything to concrete.

T.J. wrote:

So, I guess it's not a good idea to store large quantities of materials that burn under a bridge that can be damaged by heat? Genius. I'm glad nobody was hurt and once again glad that do not live in or near any large cities.

This is what I was thinking, the fire Marshall would fine me like crazy if I had some cardboard boxes under my stairs but the city conveniently overlooks enough flammable items under a bridge to take out 6 lanes? Sheesh. Also, how much stuff will "have been moved" to this location on paper since it has gone missing over the last year?

I used to go running in that area. There are some abandoned railroad tracks that intersect near there. I often find homeless taking shelter down there. I bet it was a little campfire gone wrong. Remember, only YOU can prevent PVC fires.

In reply to maschinenbau:

Hobos ruin everything

Woody wrote:

They should be able to find a cheap, rust-free section of replacement bridge on Atlanta Craigslist. And they're lucky because they won't even have to trek down to Atlanta to get it.

That's funny right there...I don't care who you are!

alfadriver wrote:

secretariata wrote:

alfadriver wrote:

So the not quite so bad observation- it looks like it's pre-cast and stressed concrete. So the structural part may be able to be done not quite so slowly.

Bummer, though.

Depends upon the condition of the supporting structure. Fire & heat can do some pretty serious damage to concrete. Also, with prestressed concrete beams there is a lead time to get into the plant and have them fabricated. Normally the schedule is probably 15-20 weeks, but with enough $ you can shorten that to a couple of weeks.

Saw a picture this morning- it was a bundle of re-bar. Which is to say that the foundations are gone.

Still- while those are being built up, the pre-made parts can get started immediately. *Hopefully* it will be only a couple of months.

Bet it's the last time PVC is stored underneath.

I've been out of the loop today and haven't kept up with this, but yeah I figured the substructure was probably pretty well past "that'll buff right out"...

Do we know who was storing the PVC pipe under the bridge? I can't imagine GA DOT would do that. Sometimes prior land owners are allowed to retain access and the DOT acquires an easement or "air rights", other times local government is allowed to use or given ownership of land under bridges, and sometimes people/businesses use the property without authorization.

They said that three people were arrested this morning on the news that they think had somthing to do with the fire.

In reply to dean1484:

Article I read said, "transients"...

I guess building a campfire in a pvc pipe can be added to the list of bad ideas.

SVreX

MegaDork

4/1/17 12:53 p.m.

MrJoshua wrote:

In my totally non-professional opinion the bridge project should require fewer businesses to work together which should help.

In my reasonably professional opinion, I disagree.

Big contractors have relationships with subcontractors which enable them to put a lot of heat on the subs when necessary. With enough money, it's not hard to get construction trade companies moving.

Reconnecting existing utilities is pretty self-explanatory. No engineering required, no permitting process slowdowns, no DOT, no OSHA, etc.

The big slowdown to a job like the Atlanta project has nothing to do with various trade subcontractors. It has to do with engineering, regulation, and manufacturing lead times. All of these are outside the control of a contractor, no matter how big.

They don't get to just put stuff back. They will have to analyze the failure, engineer new systems (in keeping with today's codes, not 20 year old codes), work with the DOT (both state and federal), develop EPA (GPA) plans, re-route traffic patterns (in accordance with the laws), etc, etc.

It would be much easier for me to coordinate 20 subcontractor companies in Japan then try to get a major road project done with 2 or 3 vendors in Atlanta.

This happened a few years ago in Oakland, CA. A contractor won a $5 million bonus on a sub $1 million bid by repairing it in 25 days.

Oakland overpass repair

Yesterday, I needed to get from Midtown to I-85 north. Usually a 1 minute trip. The 6 mile detour took close to 50 minutes; workers were coming out of their buildings to take pictures of the traffic. Not excited for every detour to be packed these next few months.

I feel bad for the ATL folks, but not as bad as the ones in Mpls with the I35 bridge collapse...