So, I was gifted a well worn, but operational Craftsman Leaf Blower. It worked fairly well, but the pull start had some hitch in its giddy-up. The cord often didnt retract all the way, and it took approximately 9,045,361,541,263 pull attempts before it would start...give or take. However, once it was going, it would blow for days (thats what she...uuhhh, nevermind).

Well, yesterday, after the first eleventeen thousand yanks, the thing coughed out a few plastic bits. Not good. The following yanks yielded very little friction.I knew immediately that the start mechanism had given up, but I was curious about the extent of the damage. So, down the rabbit hole we go

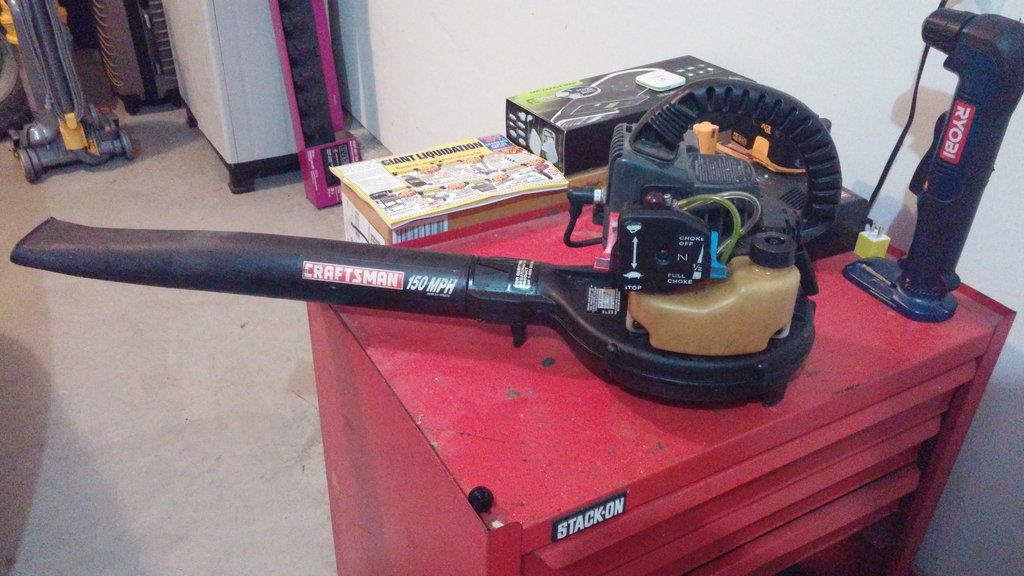

Let's get started. Oohh, look, I found some clear horizontal workspace in the garage (thanks to my father in law downsizing, I have this handy rolling toolbox/bench).

Next, we need a victim...err...subject

Take the bottom cover off, and the output tube, and you see the impeller

Remove the impeller (what a treat that was), and you see the screws that hold the engine to the base plate

When you remove the base plate, youre left with just the starting mechanism.

Be careful when you remove the starter cassette, because there is a clockspring of doom inside

OK, so, then, you spend the better part of your evening cursing and kicking things while you try unsuccessfully to reinstall the demon-spring. Then, you google it, and figure it out. Once youve removed all the skin from your fingertips, and narrowly avoided a massive, stress induced cardiac event, you have the thing back together, and you can really see whats wrong. Oh, heres your problem, most of the teeth are missing from your pull start pulley.

And thats where we stop for the day. A new pulley is $15 or so, shipped from Amazon. Of course, none of the Sears locations on the planet stock parts anymore. How else are they going to succeed in their plans to go out of business if they dont begin failing to have things in their stores that people want to buy? Undeterred by the lack of business savvy found by the Sears and Roebuck Co., I formulate a plot.

The starter pulley mechanism is there to rotate the engine up to a speed where it begins self-sustained combustion. Cars do this with an electric starter, which is basically, just a motor that engages the crank (well, the flywheel technically, but lets not get caught up in semantics). I know Ive seen commercials recently that show small engine equipment being started with a hand held thingy. I have an electric hand held thingy that also can drill holes.

And, if you look closely at the 3rd pic, there is a 14mm nut at the end of the crankshaft that holds the impeller on. Im betting that I could simply cut out a small hole in the bottom of the base to allow access for a 14mm socket on the end of an extension, and use my handheld drill to spin the crank to start the thing. Even if I cant, Im not hurting anything by trying, I can order the new cassette pulley if this fails.

I will take another crack at it tonight, and will fill you all in on what I find. Ive been wanting to try direct driven electric start on this thing ever since I got it - starting it sucked, but it ran so well once it was going, that I couldnt just walk away. Im pretty excited to try it out...