I bought a fairly large piece of aluminum off face book marketplace. Is there a way I can id or at least guess at the type of aluminum it is? Ie 6061?

It is about 9/16" thick and 36" wide and about 10' long.

I bought a fairly large piece of aluminum off face book marketplace. Is there a way I can id or at least guess at the type of aluminum it is? Ie 6061?

It is about 9/16" thick and 36" wide and about 10' long.

From United Aluminum. Most rolled aluminum sheet is 3003.

The most common type of rolled sheet aluminum is 3003 aluminum:

Composition

3003 aluminum is a commercially pure aluminum with added manganese to increase its strength by about 20%.

Properties

It has excellent corrosion resistance and workability, and can be deep drawn, spun, welded, or brazed.

Edit: One site I went to said sheet is ueually stampd with the four digit identifier every few feet. YMMV.

The best you can do without a lab analysis is an educated guess, unless there are some kind of markings on the piece, or the PO can provide some clue.

edit: at 1/2" thickness, the industry seems to prefer the term "plate" rather than "sheet".

Thanks the PO said it came as a package deal with a two post lift that he bought, so he didn't know much about it.

I didn't look anywhere to see any stampings, I will have to look at it closer.

In reply to Datsun240ZGuy :

I've been keeping an eye out for some thicker aluminum to make a transmission adapter plate from, for a potential challenge car idea I have, and this came up so I just went for it. I figured I can have the adapter out of this and then still have lots extra down the road if I need something later on.

He had two sheets and I only bought one. So he still has a sheet left if anyone needs something like this I can pass along his info.

The most common alloy will certainly be 6061. That is what most metal suppliers keep in stock. For me 3000 or 1000 series is special order.

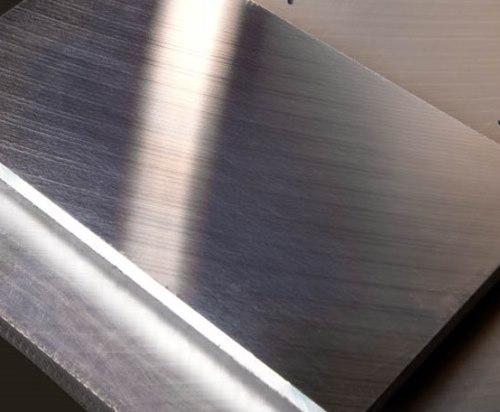

Is the surface the smooth one of the normal extruded/rolled product or does it have the tell tale surface grinding marks like this?

If it has the blanchard ground surface, it might be MIC6 which is a cast product. You can drill it and if it makes long chips it isn't but if it makes a powdery pile it is likely MIC6, which is still a great alloy.

Please stop calling this "sheet". 914 Drivers comment from United aluminum is correct for sheet. If you drill it and it seems sticky it is probably 5052, if it drills with proper chips Trent is correct about 6061. If it is MIC6, or anything with a machined finish test a piece for brittleness, all of the"jig plate"alloys like MIC6 are rather too brittle. 5052 and 6061 will deform some and fracture more slowly than MIC6. 3000 series alloys are rare in plate thickness, although 3003 is great for welding and brazing, but it machines terribly, it sticks to tools worse than 5052. You have enough to do proper destructive testing so you can use it correctly. Personally I would not use MIC6 for a bell housing adapter because of the brittleness and related vibration induced failures. Any other alloy in 1/2" plate will work OK for that job, and if it machines easily it is 6061. at least with the suppliers in Pennsylvania if the original purchaser bought it from stock it is 6061 or 5052, everything else is special order. Mill marks are not stamped, they are painted on, and come off with lacquer thinner, so good luck there.

I wouldn't think twice about MIC6 as an adapter like that. MIC6 is cast 7000 series aluminum that has been stress relieved. I guarantee it is better quality and stronger than the bell housing it would be bolted to.

Anything with shock loads? Heck no. As a flange adapter? It'll be the nicest one around

I would bet you could find a machine shop nearby, or possibly a lab that would have a hardness tester.

Wont give you an exact ID, but it will help narrow it down with some other specifics like Turner's suggestions

In reply to Trent :

Similar on the East Coast. Look at the photo. Doesn't that look like a lift post bolt pattern? I would bet 98% this is 6061 T6. Bought with a lift. This was someone's reinforcement for an install on an iffy floor.

In reply to TurnerX19 :

There are threaded holes on each end of the plate. Is that a common thing to use a plate to reinforce lift mounting?

You'll need to log in to post.