I've used mechanical splices, which are sorta cheesy and prone to moisture, I've used the mechanical butt connectors, I've soldered, and I've used the shrink solder butt connectors. I like the latter the best so far- but big question- what is the preferred method for joining three wires in a low voltage (12v automotive) application?

Thanks in advance!

Soldering is the only way.

pres589

PowerDork

1/22/18 2:49 p.m.

It Depends.

Small gauge stuff, not a pile of amperage, a butt splice and heat shrink is probably where I'd go. A terminal block is nice when you have some space to mount and you need to deal with a real amount of amperage. I've used this in the past; https://www.bluesea.com/products/2315/Common_100A_Mini_BusBar_-_4_Gang_with_Cover

Sometimes it's solder time but I really don't enjoy that much and avoid when I can.

I'm sure there's a ton of opinions on this.

Soldering vs crimping, always fun on a car forum  I'm in the crimping camp because that's what the manufacturers do and they last for decades. Use a ratcheting crimper and they're solid.

I'm in the crimping camp because that's what the manufacturers do and they last for decades. Use a ratcheting crimper and they're solid.

For a three-way join, you can get crimp connectors that have staggered sizes. Two wires go in one end, one wire goes in the other.

https://www.delcity.net/store/Clear!View-Heat-Shrink-&-Crimp-Step-Down-Connectors/p_809306.h_809307

In reply to Keith Tanner :

Someone dropped the ball by not calling them Thunderdome Connectors.

slefain

PowerDork

1/22/18 4:15 p.m.

I use wire nuts when I'm laying out a circuit. Once I'm happy with how it works I solder and heat shrink the connections.

I'm with Keith in the crimp camp. I have yet to have a connection fail. I use the heat shrink crimps. They even survive in the boats without corrosion or vibration problems.

Keith Tanner said:

Soldering vs crimping, always fun on a car forum  I'm in the crimping camp because that's what the manufacturers do and they last for decades. Use a ratcheting crimper and they're solid.

I'm in the crimping camp because that's what the manufacturers do and they last for decades. Use a ratcheting crimper and they're solid.

For a three-way join, you can get crimp connectors that have staggered sizes. Two wires go in one end, one wire goes in the other.

https://www.delcity.net/store/Clear!View-Heat-Shrink-&-Crimp-Step-Down-Connectors/p_809306.h_809307

Where have these been all my life?

I'm doing those solder/shrink non-crimp connectors on my Airstream resto- but found one I thought was sound, and it just pulled apart. Brakes!!

Toyman01 said:

I'm with Keith in the crimp camp. I have yet to have a connection fail. I use the heat shrink crimps. They even survive in the boats without corrosion or vibration problems.

Heat shrink is a given, regardless of how you like to stick your wires together  A good crimp will be stronger than the wire.

A good crimp will be stronger than the wire.

I'm not personally a fan of the self-soldering connectors as I don't think they have the same mechanical strength, but I don't have any testing to back that up. They're definitely easier to get wrong than the crimps.

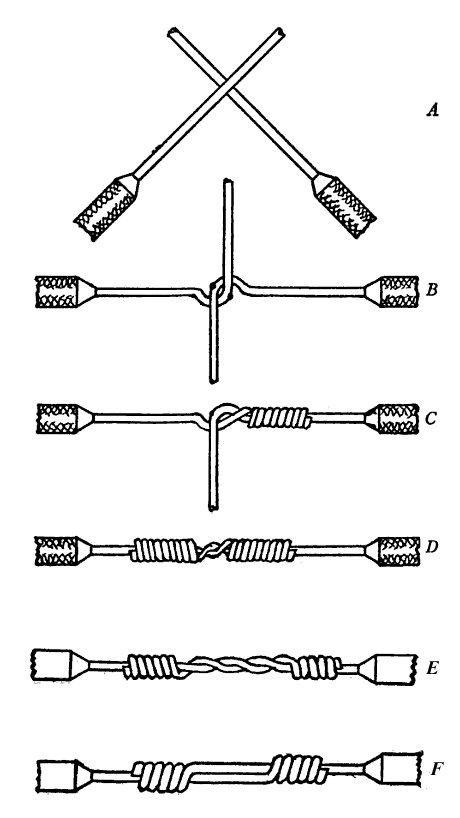

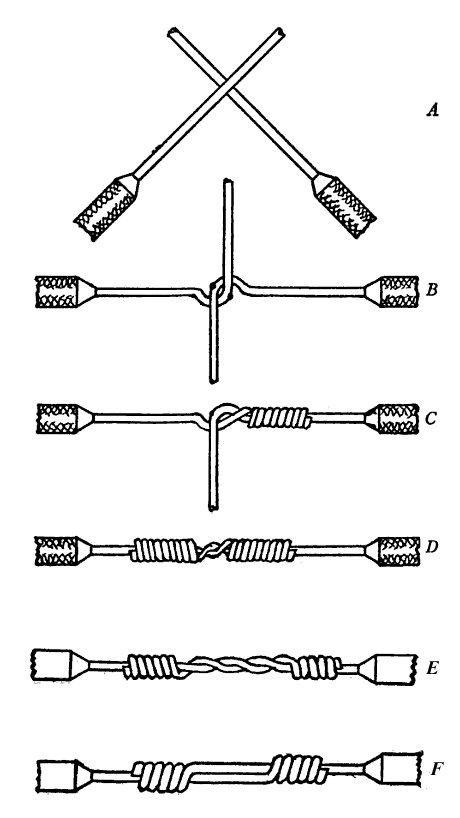

Western Union splice anyone?

I solder and shrink wrap everything automotive.

Ain't that much to do really.

8valve

New Reader

1/22/18 6:38 p.m.

Solder all the things. Even crimp connectors.

I solder anything I actually care about, butt splices might see occasional use for a quick repair.

IIRC military spec is for crimp, heat shrink and stress relief. Not solder. Can anyone confirm?

I taught soldering and crimping in the Navy Nuclear field, and if the wires are ever exposed to movement crimping was the only option allowed. Between the corrosion caused by the hot flux and the temperature hardening of the wire near the joint solder joints don't hold up as well long term. In fact solder is only allowed if it can be thoroughly cleaned afterwards to get every trace of flux off.

A proper crimp joint, with a ratcheting crimper, pressure welds the wire to the lug. If you really want to do it right get uninsulated silver plated lugs, a good crimper, and a roll of heat shrink tubing. Save the solder for inside stuff with strain relief.

In fact, my preference is for the Western Union splice, or some version of it, over a soldered joint by a huge margin.

fasted58 said:

I solder and shrink wrap everything automotive.

Ain't that much to do really.

Until you chop an LS engine harness into 3 pieces and toss into the wire scrap can, then realize you need to dig it out and piece it back together for a challenge car. Yeah, that took 15+ hours.

Yes Keith, it is the current spec for military. At least for army aviation it is.

When I retired from military aviation and had to buy crimps I admit I started soldering. When I did wiring work on helicopters, always grabbed a handful of splices. Never used them all and they ended up being emptied out of my pockets when I got home so had some when I needed it. Eventually ran out after I retired and lost my source so ended up buying some from the local parts store. Have had failures with these so started soldering. Guess I'll have to find a source for quality splices. And get a ratchet crimper like I used in the military. The cheap crimps you get at the parts store aren't worth the time and effort. A good quality butt splice used properly is better than soldering. But soldering is better than a cheap crimp.

pres589

PowerDork

1/22/18 9:45 p.m.

Mil helicopters use both. It's all about the right termination for the situation at hand. Strain relief is as important as the termination type. One reason I like crimping is that it doesn't use heat.

The SAE, FAA, and ABYC all recommend or require crimped connections in most applications.

wlkelley3 said:

Yes Keith, it is the current spec for military. At least for army aviation it is.

When I retired from military aviation and had to buy crimps I admit I started soldering. When I did wiring work on helicopters, always grabbed a handful of splices. Never used them all and they ended up being emptied out of my pockets when I got home so had some when I needed it. Eventually ran out after I retired and lost my source so ended up buying some from the local parts store. Have had failures with these so started soldering. Guess I'll have to find a source for quality splices. And get a ratchet crimper like I used in the military. The cheap crimps you get at the parts store aren't worth the time and effort. A good quality butt splice used properly is better than soldering. But soldering is better than a cheap crimp.

Delcity.net. I think they work out to about 12 cents each. I buy them about 100 at a time. The auto parts ones are more expensive and less reliable.

In reply to Keith Tanner :

Recommend a good ratcheting crimper?

There are whole bunch that look identical. I can't remember the branding on mine, but I think it's a Tool-Aid.

https://www.amazon.com/Tool-Aid-18900-Professional-Ratcheting/dp/B0002STTSY/

Mine has five sets of interchangable jaws for different types of crimps, but I only ever use the ones for insulated terminals and occasionally the ones for ECU terminals - but those are easily done with a non-ratcheting tool if you have one. Looks like this one has the insulated terminal dies, so let's call it the best bang for the buck.

Ah, here's my set.

https://www.amazon.com/Tool-Aid-18920-Ratcheting-Terminal/dp/B0002STTTI

Reviews would indicate this is New And Improved, with longer handles (more leverage) and a better placed release.

https://www.amazon.com/Tool-Aid-18960-Ratcheting-Terminal/dp/B006O1Y1FY/

Here are the terminals I use. Looks like prices have gone up from what I remember, but I don't think I've ever had one fail.

https://www.delcity.net/store/Heat-Shrink-&-Crimp-Butt-Connectors/p_805404.h_801795

And the belt/suspenders/duct tape combo: crimp/solder/heatshrink.

https://www.delcity.net/store/Heat-Shrink,-Solder-&-Crimp/p_805407.h_801820

"environmental splice"is what you're looking for. It's the aviation standard, stronger than the wire itself, but requires special crimpers.

http://www.newark.com/raychem-te-connectivity/m81824-1-1/terminal-butt-splice-crimp-red/dp/24M0186