Ok folks I'm at a loss here. I'm having a hard time understanding what's going on here and am turning to the collective minds here.....

Ok, get ready for a long story, though I'll try to keep it short.

I'm running a centrifuge (CF from here on out) and love it. Back in the summer I was getting condensation in the hose coming out of the CF going into my "clean barrel". The hose in question is a 3/4" hose that only has a small amount of oil in it, so there's lots of air in the hose, 7/8 of the volume I'd guess. I called the CF folks and they said they hadn't come across this issue before. They said I should remove the two plugs on the lid of the CF allowing airflow through. That didn't do anything really. I then put a plastic "T" on the hose right at the CF out fitting. This did the trick. I'd actually see vapor leaving the "T".

Cool................until yesterday. I have condensation again. My questions are:

1) Why

2) How to avoid it.

I don't know the actual temp of the oil flowing through the hose but I'm sure it's 100 - 130 degrees F higher than ambient temps right now. After everything cooled down yesterday I tried using a hair drier to warm the hose and filtered again. No condensation. So I have two ideas:

1) Put a gate valve at the output of the HOSE, keeping the hose full of oil all the time thus having no air space in the hose at all. The only draw back is when I adjust the flow of oil into the CF I"d have to match that flow at the output hose or I'd overflow the CF.

2) Heat tape on the hose to warm it up.

If I take option #1 I'm afraid I'd move the point of condensation from the hose (where I can see it and know it exists) to the "clean barrel" where I couldn't see it. The volume of air to volume of oil ratio is waaaay different when we're talking about an empty 35 gallon barrel though.

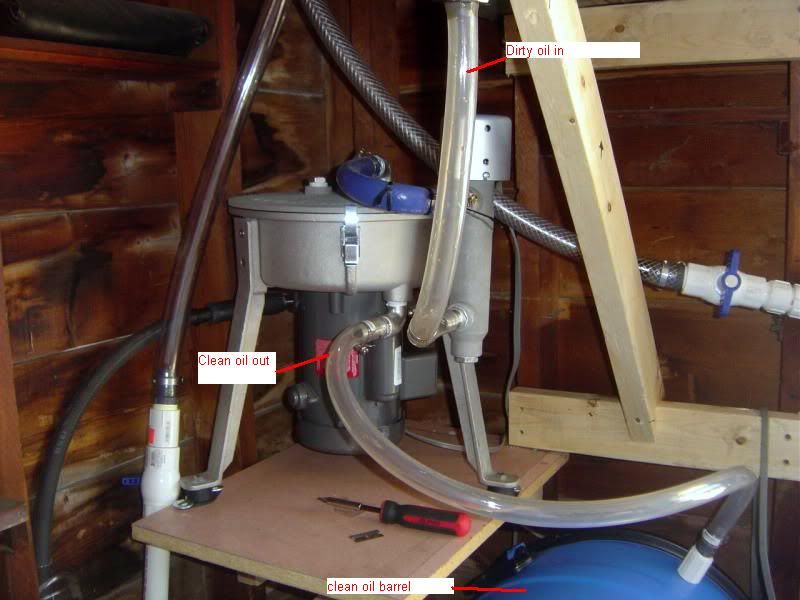

Here's a pic for reference. This pic doesn't reflect the plastic "T" I installed or the reinforced hose I just recently switched over to after my BP oil spill.

I hope all that makes sense....