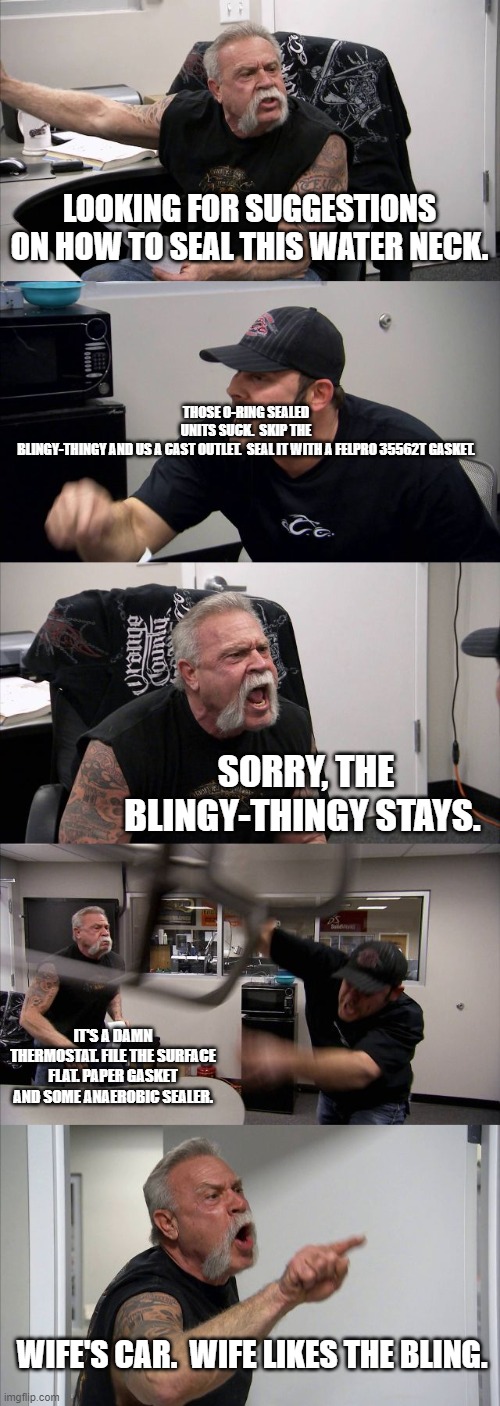

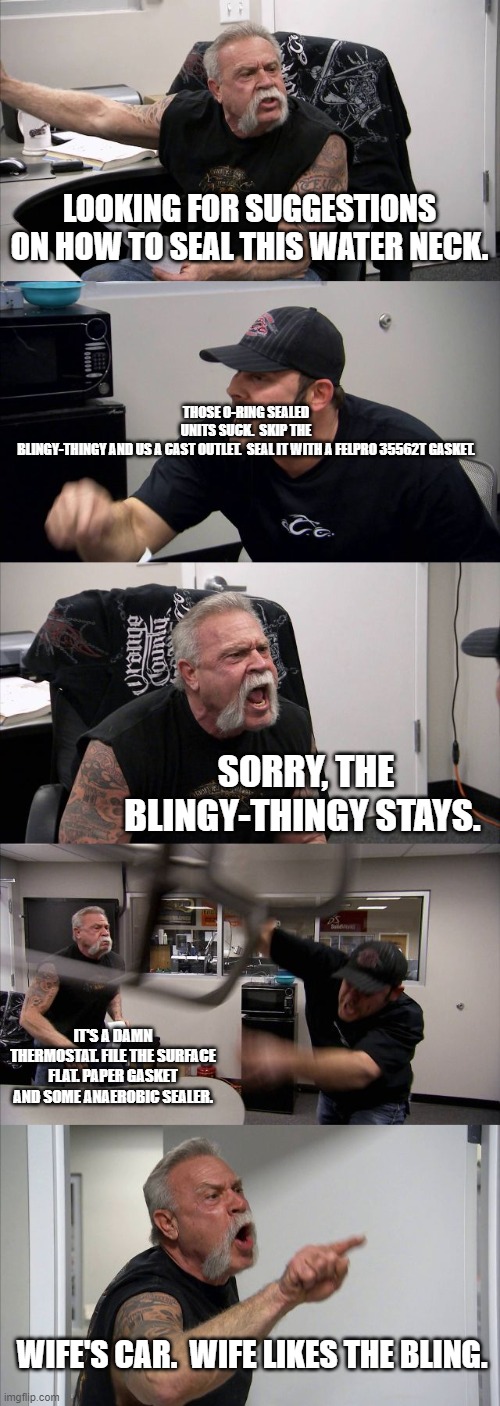

Putting the finishing touches on the Chevy II. Adding fluids. Got the bling-ey Billet Specialties water neck. It comes with a nifty rubber O-ring that will contact the surface of the manifold just outside the thermostat. Problem is, that area is a mite pitted. How to proceed? Ship it? Add a gasket? Add a gasket sealer? RTV?

TIA!

ShawnG

MegaDork

3/23/24 11:05 a.m.

Those o-ring sealed units suck.

Try some anaerobic sealer on the flange before you put the water outlet on.

Skip the blingy-thingy and use a cast outlet. Seal it with a Felpro 35562T gasket. You could try this gasket with your fancy outlet and see if you get lucky. Its plastic with a rubber seal, much bigger than a o-ring.

I wonder if you could fix those pits with a little epoxy or JB weld.

Gearheadotaku (Forum Supporter) said:

Skip the blingy-thingy and us a cast outlet. Seal it with a Felpro 35562T gasket. You could try this gasket with your fancy outlet and see if you get lucky. Its plastic with a rubber seal, much bigger than a o-ring.

I wonder if you could fix those pits with a little epoxy or JB weld.

Ah! I had considered this. Pretty easy to do, really. I think I have some epoxy that might still be good. I think that's going to be my strategy. Even if I don't do a great job, it's bound to be better than it is.

Edit: Sorry, the blingy-thingy stays. Wife's car. Wife likes the bling.

It's a damn thermostat. File the surface flat. Paper gasket and some anaerobic sealer.

Ding! Ding! Ding!

Remove the thermostat, stuff a rag in the hole and draw file the surface, then use some emery on a hard sanding block. Ensure your strokes are east-west, then north-south to prevent curving the surface.

Hmmm. I haven't tried to measure it, but I'd say that big crater is at least 1 mm deep. Thinking I'd prefer to fill it, since some of the surface is now flat. When I get done filing it, I suspect it would be no longer flat.

And this does not quite work. So I will not take credit for it.

In reply to Noddaz :

You guys are a riot. Thanks! I need to see that she sees this.

Mix up a little batch of JB Weld. Apply it with a razor blade and it should fill in the divots nice and smooth.

I would also JB Weld the craters and then deck it with a flat file or the aformentioned block with some emery cloth. Or you wanna get frisky, chuck it up in a mill and fly cut the surface.

60-grit on a chunk of 2x4.

No o-ring neck. They bend the first time you torque them down.

It's like this board doesn't make their entire builds out of The RIGHT STUFF

Here is a thread on how to use it on everything https://grassrootsmotorsports.com/forum/grm/need-to-know-everything-about-right-stuff-sealant/85594/page1/

Paul_VR6 (Forum Supporter) said:

It's like this board doesn't make their entire builds out of The RIGHT STUFF

I'm reading the responses and thinking "why isn't anyone just using Permatex 'Right Stuff'?"

Thank you, Paul. At least there are two of us!

ShawnG

MegaDork

3/25/24 9:31 p.m.

In reply to SkinnyG (Forum Supporter) :

There's three of us but I'd rather not need a strike-thru scraper and hammer to change my thermostat.

I'd also be using the factory water neck though, mostly because I had one of those o-ring ones once.

ShawnG said:

In reply to SkinnyG (Forum Supporter) :

There's three of us but I'd rather not need a strike-thru scraper and hammer to change my thermostat.

Could always use Permatex Aviation Form-A -Gasket....

.... pity the next guy to go in there.

Curtis73 (Forum Supporter) said:

No o-ring neck. They bend the first time you torque them down.

And then you're filing them flat and using a bead of Right Stuff instead of a gasket anyway, which renders the whole "pits in the manifold" thing moot.

I hated the O ring blingy thingy thermostat outlets. They ALWAYS warped and bent and leaked.

Right Stuff is always the answer.