Are there any disadvantages of testing in a wind tunnel that's not enclosed (apart from rain and bird poop)? I figure if the fan's airflow is wide enough to cover the thing being tested, that's just as good as an enclosed tunnel, right?

Are there any disadvantages of testing in a wind tunnel that's not enclosed (apart from rain and bird poop)? I figure if the fan's airflow is wide enough to cover the thing being tested, that's just as good as an enclosed tunnel, right?

It would take more wind to cause the same desired effect and you risk lab quality, but hey, I don't see why not to give it a try.

F1 teams do it using the flo-vis paint or whatever they call it. But they just drive around track, there's no outdoor wind tunnel.

An outdoor wind tunnel seems pretty pointless.

Free wind tunnel... attach kiddy bicycle handlebar streamers (pull them apart) to the car surfaces with tape and drive fast. Use a gopro to video the areas.

People think I'm crazy at test/tune days... driving around looking like a fuzzy pinata with cameras suction-cupped in weird places... but atleast I know my wing isn't stalled and that home-made splitter is doing something more than creating lift up front. It's more confirmation than you get from people who make and sell aero stuff for big $$.

z31maniac wrote: F1 teams do it using the flo-vis paint or whatever they call it. But they just drive around track, there's no outdoor wind tunnel. An outdoor wind tunnel seems pretty pointless.

Gameboy- if your answer to this question is that you are running models- you can mount them to vehicles so that they can move in the airstream.

No I'm thinking of running cars, and doing things that you can't do on the highway with cameras, like measuring downforce and drag with scales.

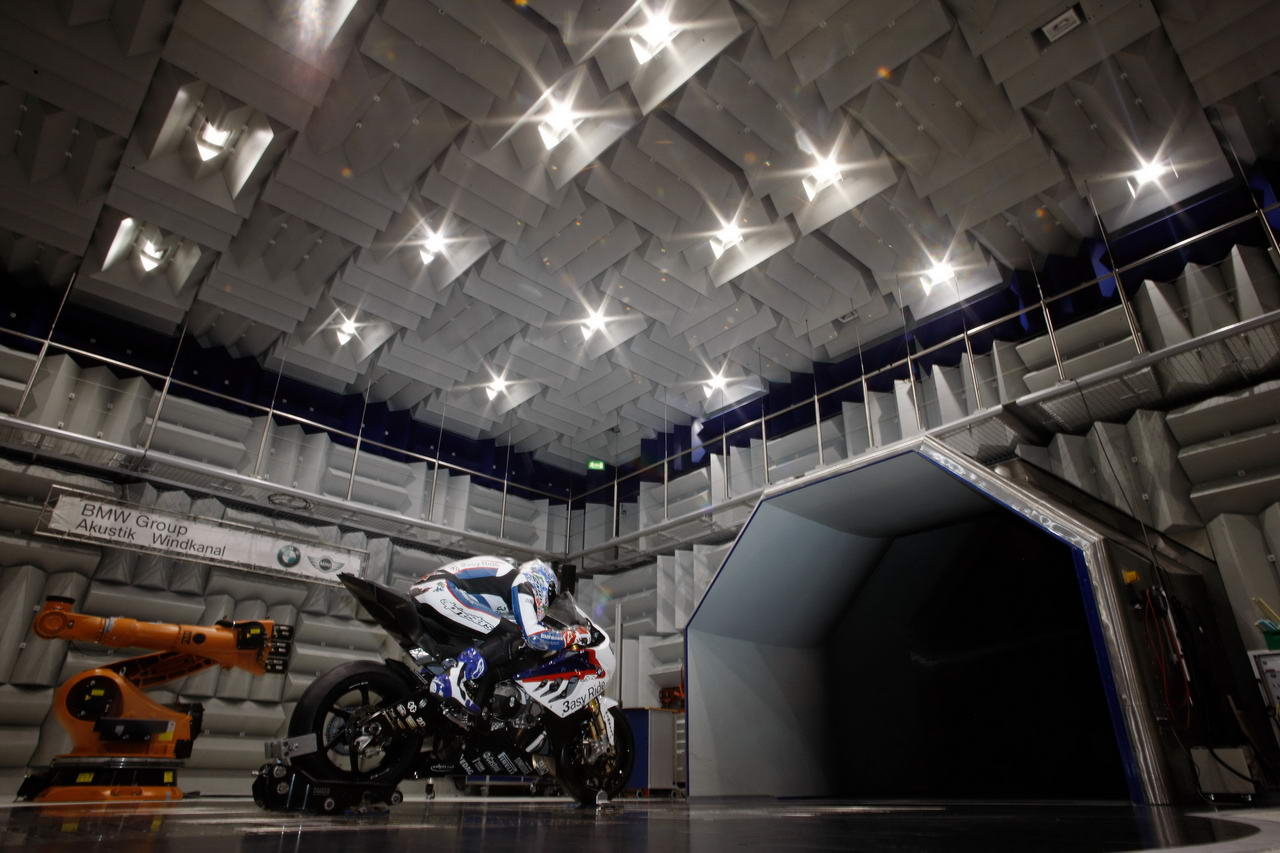

Some "professional" wind tunnels are just a huge fans in a warehouse, for example:

Aerodynamically wouldn't these be pretty similar to just parking the car behind a big fan outdoors?

GameboyRMH wrote: No I'm thinking of running cars, and doing things that you can't do on the highway with cameras, like measuring downforce and drag with scales. Some "professional" wind tunnels are just a huge fans in a warehouse, for example:

Please remove the quote tags from professional if you are referencing the pictures in your post. NONE of them are "huge fans in a warehouse". If you believe they are, I'm fairly certain you've never been in one, and it detracts from the rest of your post.

That being said, paint droplets and streamers to calculate stall angles on a wing as discussed already are perfectly reasonable methods of outside aero testing (see GPS and z31's posts).

Flynlow wrote:GameboyRMH wrote: No I'm thinking of running cars, and doing things that you can't do on the highway with cameras, like measuring downforce and drag with scales. Some "professional" wind tunnels are just a huge fans in a warehouse, for example:Please remove the quote tags from professional if you are referencing the pictures in your post. NONE of them are "huge fans in a warehouse". If you believe they are, I'm fairly certain you've never been in one, and it detracts from the rest of your post. That being said, paint droplets and streamers to calculate stall angles on a wing as discussed already are perfectly reasonable methods of outside aero testing.

I know they're more like a huge set of fans with a building on it, but my point was that the chamber where the testing is done is MUCH bigger than the air stream, vs. the type where the chamber is just the width of the air stream.

They're all set up by professionals, no harm meant by the quotes, there's no proper word for a wind tunnel set up by professionals is there? ![]()

Hey Flynlow is just who I need! I realized from the amount of offense I caused that Flynlow must be an aeronautical engineer who works with wind tunnels, and his profile info matches up!

So apart from potential contamination from outside wind, what are the problems with an outdoor wind tunnel?

My understanding is aeronautical tests can run in the enclosed tunnel because an aircraft is passing through a free air stream, so as long as the tunnel is large enough to move the boundary wall effects away from the model, this is the preferred configuration. Suspending a car in a round wind tunnel would not make sense, because any vehicle being driven has a large groundplane it never leaves, and disregarding the effects would render any aero changes you might make meaningless. In addition, this is why moving groundplane tunnels are so popular as aero becomes a bigger part of fuel economy needs for OEMs, to simulate the rolling road on an otherwise stationary vehicle in the tunnel. However, introducing this flat ground reference requires a square test chamber, with corresponding higher (and variable, as you approach each corner) boundary effects. Therefore, you enlarge the chamber as much as economically possibly to try and get as close to a true measurement as possible around the vehicle.

The rest of an average tunnel, FYI:

Your pictures pretty much only showed the balance platform.

GameboyRMH wrote: Hey Flynlow is just who I need! I realized from the amount of offense I caused that Flynlow must be an aeronautical engineer who works with wind tunnels, and his profile info matches up! So apart from potential contamination from outside wind, what are the problems with an outdoor wind tunnel?

Ha! No offense taken, sorry if I came across as harsh...just something about putting multi-million dollar wind tunnels in the same league as fans in a warehouse made my head kind of explode. Also, it was right before lunch. I am actually not an aeronautical engineer, but I did work in car aerodynamic design for a while. Though I was the low man on the totem pole, with only a BSME in a room full of PhD's.

To answer your second question......lots. If you're hoping to set up a test rig with just a shop floor fan (like what you see in dyno tests) and some chassis scales......good luck. Some background reading for you:

http://green.autoblog.com/2010/08/05/gms-wind-tunnel-turns-30/

I used to work for a company that built wind tunnels (I'm not an aerodynamicist, I designed the controls.) In fact, I think I did some work on that one in the black and white photo above.

It will depend on what kind of testing you have in mind. I doubt you'd be able to get enough fans and enough horsepower to do anything with a full size car, but you could maybe come up with a way of testing scale model cars. Unlike the pictures you often see of a guy standing in front of the model with a wand emitting smoke to show the air flow, typically the object being tested (whether it's an airplane or car or bike or whatever) is fastened to an arm or base plate, connected to strain gauges that monitor the forces on the object. There are also a lot of fins and things in the tunnel to straighten out the air so you're not just blowing a bunch of turbulence around.

I have seen science fair projects that used a regular old window fan and a tunnel made of cardboard and plexiglass, with a model car or plane in them. They aren't going to provide precise results but they can generate general numbers, and something like that could work for doing comparison tests - say, test a stock body model car, modify its shape, and test it again to see if the modifications helped or not.

Alternate option: put the car on a trailer and tow it. Sure, you'll have some wake effects from the tow vehicle but you can do a few things to minimize that. A long trailer with a relatively high deck and a reasonably clean tow vehicle, for example.

Also, to monitor things like downforce, you could measure suspension deflection. You can get ride height sensors off a whole range of junkyard cars for next to nothing and datalog them. I've actually got the parts to do this at home as part of a "someday" project.

To measure drag, use a simple coast-down test.

Velocity Aircraft actually truck mounted one of their aircraft on a truck based rig to do some deep stall investigation work-- picture and article at the link.

Keith Tanner wrote: Also, to monitor things like downforce, you could measure suspension deflection. You can get ride height sensors off a whole range of junkyard cars for next to nothing and datalog them. I've actually got the parts to do this at home as part of a "someday" project.

I actually tried to get these same sensors but couldn't find them in a junkyard...well I found one or two cars that had them but the fasteners for them were rust-fused ![]()

Flynlow wrote: If you're hoping to set up a test rig with just a shop floor fan (like what you see in dyno tests) and some chassis scales......good luck.

Actually my idea was not too far off this. I know I'd need a much bigger and more powerful fan, I'm thinking 15-20ft blade diameter.

Gameboy, as someone who does spend a few days a week in wind tunnels, working on cars, there is more to the test section than a large room. Also the fans running most tunnels are larger than the test vehicle, but the flow area is reduced significantly to get the flow speed up and reduce the turbulence levels. The other portion of the enclosed test section/tunnel is ambient control - no cross wind, controlled temperature, possibly controlled humidity, etc. Moving ground planes mentioned above are not the only way to get rotating wheel effects. Mounting the wheels on dyno type rollers will get you closer than a plain floor, but you still won't have zero boundary layer thickness on the floor under the car. Early auto testing of underbody effects were done with a model that was mirrored at the ground surface (imagine two cars bolted together at the wheel contact patches). The equal and opposite effect of the shapes effectively gave a ground surface, but it makes it difficult to measure downforce when the models cancel each other out. There are lots of little details that make a wind tunnel work well (and accurately). What you have envisioned will get you some basic information, but it will not give you the most accurate answer.

Power will be the biggest challenge. Most tunnel are full return as pictured above. That lets you maintain almost all of the energy put into making air speed minus the drag of the tunnel and the energy turned into heat to make it all work. As an example of the two tunnels I use regularly one use 22 100HP fans to get 130mph, while the other uses a single 5000HP fan to get 175mph. Another tunnel I used to use had a 500HP fan to drive to 140mph for a half scale tunnel.Lets just say the power company like to see them start up.

On another note, there is a term for wind tunnels setup up by professionals - Commissioned. That generally requires some sort of report showing the tunnels performance and limitations. This turns into the technical document used to decide if a tunnel is going to work for potential customers.

If you have other questions, lets hear em. Later, Stafford1500.

stafford1500 wrote: As an example of the two tunnels I use regularly one use 22 100HP fans to get 130mph, while the other uses a single 5000HP fan to get 175mph. Another tunnel I used to use had a 500HP fan to drive to 140mph for a half scale tunnel.Lets just say the power company like to see them start up.

If I recall correctly, the 80' x 120' foot tunnel at NASA Ames in California has a total of 365,000hp worth of fans. ![]() They have to call the power company first before they can turn that thing on.

They have to call the power company first before they can turn that thing on. ![]()

Man, I was thinking I could power it with a V8...it would be cheaper than electric around here for sure.

Yeah this was for a business idea. There are no wind tunnels here, and even the rich guys who could afford to send their cars overseas for testing would still have to suffer with the delays. I figured I could start ghetto and then spiffy up ![]()

Best and cheapest outdoor wind tunnel.. Is a DIY car wash.

Select the high pressure spray. Rinse, soap, or Hot Wax is up to you.

Hold the nozzle so the spray is more or less even with the profile of the hood. Have a friend or Go Pro cameras record the profile of the liquid as it moves toward, then over the windshield, then back toward the rear of the car, usually arcing back down with the profile of the rear window then trunk lid. Discard the first few seconds of video since you have to give the water and air around it to get up to speed. It can also be used with the side profiles and front of the car. For those just adjust where the nozzle is located.

If you really want to get serious with this method. Buy a pressure washer, and build some jigs to accurately repeat the tests.

I've seen (and played with) a similar setup including an air nozzle with a long nose and a string. It's a single stream line, but it'll display things like stalled airflow and turbulence surprisingly well. You can play it over the car and get a good idea of the three dimensional airflow.

You'll need to log in to post.