mount for bike pump

What a great idea for a thread. I'll try and remember to post when I print stuff. I humbly suggest that folks put the printer and fillament in their posts.

Bumping this to see what everyone else has been up to.

Ive been busy with illness and moving, so havent done much work on the van. I made this to hang a whiteboard yesterday though:

Test pieces (clearly I did not bring my A game)

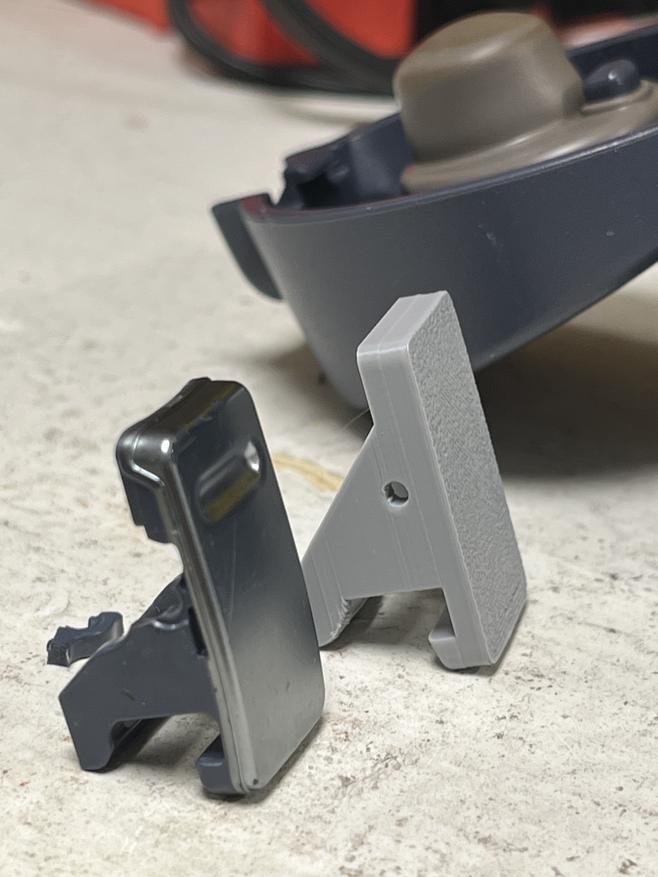

Made an adapter for my bike fork mount to replicate the shoulders found on the wheel hub meaning you can align the thru axle 1 handed instead of an awkard 2-handed deal.

The latch on SWMBO favorite travel coffee mug broke. Someone had already modeled it online, so no problem!

I've been having issues with my Ender 3 that maybe some of you guys can help with?

I had a foul up over the summer that caused about a 5 hour print to basically engulf the entire hotend/nozzle/fan assembly. I cleaned it off as best I could and put on a new nozzle. Never could get it to print smoothly again. So just recently I saw Creality had their direct drive extruder for just as cheap as a new hot end. Bought it, swapped it on and the first print was glorious. Like, the best it's ever been. Go for a second print and it errors out immediately. At rest, nozzle temp shoes 358*. A little googling shows some people having this issue on a new hotend install and I should just crack the thermistor mounting screw because it's over tightened. Well, I did that and it goes back to normal but halfway through any print it shorts, goes full heat and errors out. Suggestions? Did I break the thermistor?

Prototyping Formula Ford suspension mounts for different control arm vertical height mounting options. Printed parts can be bolted up to check for things we didn't consider when coming up with the concepts.

Once we're happy with the design we send it out for CNC production. First time we're trying this, so hopefully the prototyping step saves iterations in production parts.

Printed this gem this morning:

Looks like it was a bed adhesion failure. Cleaning the bed and giving it another go.

I'm an old clock enthusiast and while this 70s Schmeckenbecher automaton is about 100 years newer than my period of interest, my grandparents had one just like it and the chime reminds me of Saturday morning at their house. This one was missing the four brown beams at the top and the hammer propped up on the anvil. I was using a Lego axe in place of the hammer, but a clock popped up on eBay and I was able to get the dimensions of the missing parts. Printed and painted, the new parts look great.

In reply to Mr_Asa :

I was looking at the A1. Is the multiple color head worth the extra 150 for a beginner over the single color model? Just not sure I would actually use the multi color that often or really at all. Mostly looking for maybe some custom bits for the car or some hard to get plastics etc maybe some things for the drones. Biggest thing I thought about is an actual fixed wing drone chassis but even that I would imagine I would only use a single color.

I've had an AMS for a year and have never done a multi-color print. We have 4 of them we run daily at work and we've never done a multi-color print.

Its a selling point for people who do more crafts than functional parts or eng. prototyping.

for prototyping we mostly use resin printers at my work, and we have a few different resins we swap out for different mechanical properties. we're able to hold suprisingly tight tolerances on parts made with them

Doesn't a multi-color head also allow you to use a soluble support filament?

My most recent print is a bracket for a bunch of hockey sticks. Naturally, I started with a downloaded design and by the time I was done I'd redone it from scratch.

Also, built this holder for my Apple TV remote so I can stick it to the side of my toolbox in the shop. Again, some redesign work.

Also, no pictures for you at this time - but a coworker has a giant Creality printer that's big enough to do a wheel. So when we were looking at some proposed renderings of our next design, we printed one so we could check it out in real life.

No pictures handy (I took them a while back and I'm not up for that much scrolling) but you can download 3D files of just about everything from McMaster. I had some AN lines that I wanted to keep clean, so I downloaded an AN plug from McMaster and printed it out.

Also, on a higher end, we have two turbo cars running around with printed stainless manifolds and turbine outlets. This is as received, no machining or surface treatment. There was a little bit of stringing (in stainless!) inside that we had to clean up but the outside is beautifully smooth. I think they were FDM with a sintering post-process.

In reply to z31maniac :

Mine collect dust about 90% of the time, much like my hydraulic press. That other 10% it sure is nice to have around though. Much like the hydraulic press, it seems my friends get more use out of it than I do, but they return the favor with access to their toys, like the CO2 laser engraver.

If mine were faster, I'd probably use them more often, which is why I keep looking at resin printers. They might not be faster, I'm not sure, but the difference in post processing seems a fair trade off.

In reply to pkingham (Forum Supporter) :

Forgot I'd posted this. Now a pic with the final aluminum CNC machined parts. Worked out great. This pic also shows the evolution of the prototypes, all of which were bolted to the car at some point.

It's not super exciting, but it's a step towards something super exciting.

Fuel pressure regulator mount for my Locost. It's just PETG for now, I'll print it out of an appropriate material at some point.

Keith Tanner said:Doesn't a multi-color head also allow you to use a soluble support filament?

I've tried solubles. They work so-so. The real deal is that some filaments won't bond together, like PETG and PLA. They simply won't stick to each other. So if you're printing PLA use PETG as the supports with a zero interface. Perfect surface finish, and the parts come right off. Then you still have PETG to use for other prints unlike solubles that will just absorbe moisture and become junk.

Keith Tanner said:No pictures handy (I took them a while back and I'm not up for that much scrolling) but you can download 3D files of just about everything from McMaster.

z31maniac said:

I want a 3D printer "for reasons," but I legitmately don't know what I'd use it for.

Keith, you just blew my mind. Life is suddenly much better/busier.

Z31; you will never stop finding things to use it for once you have it.

You'll need to log in to post.