First, I purchased these plans: JD Garage Plans

Plans ordered from JD Garage, both version 1.0 and 2.0

Plastic parts 3D printed in PET-G, 100% fill:

"Kit," ordered from some lengths of tubing, and some parts plasma cut on the machine at work:

Crush sleeves welded at fastener locations:

Painting:

Assembling:

Assembling the Gantry:

Everything else from Amazon:

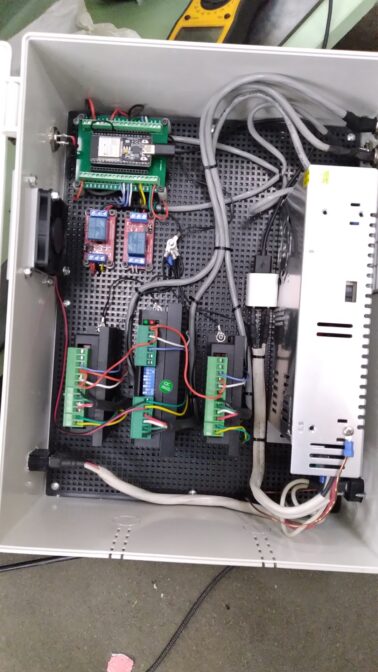

Bought v1.0 plans months before, but could not flash the Arduino. And ultimately smoked the Arduino.

Box with power supply, relay, and stepper controllers, and soon-to-die Arduino:

V2.0 plans use an ESP32 board, so I bought the upgraded plans, and two ESP32-WROOM-32D boards and completely re-wired the box. V2.0 also uses bigger wiring, which I bought locally.

I somehow I smoked Pin20 (GND) on both my ESP32 boards. I ended up just jumpering it to a good ground and got it to work fine. All except for connecting via Bluetooth. Apparently the WROOM-32U boards are actually the recommended ones, so I ordered two, only to discover that I bought "wide" boards, not "narrow" boards (won't fit the narrow Breakout Boards I have). And I still cannot connect to them via Bluetooth.

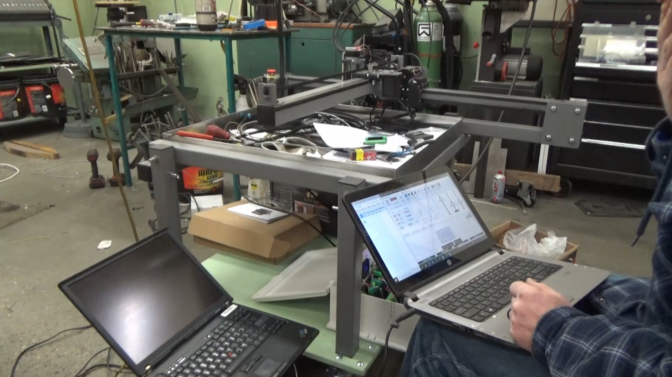

Running OpenBuilds CONTROL.

Fabricating the metal grate - 2" slots in 2.5" angle iron, and 2" flat bar supports:

The first cut I did not have water in the stainless tray. That got real exciting when the foam rubber on the underside caught fire.

There was also some significant electrical interference somewhere that made circles into mini-saw blades. I suspected carelessly routed wiring?

I had placed the machine on a rolling sheet of plywood (shown above, in machine green), with the intent that the electrical box would stay under the machine. I ran an externally-placed E-Stop, but did not adequately ground the shielding. The machine would start the arc, and then just sit there and the E-Stop would flicker the machine between Play and Pause. After properly grounding the sheathing, it worked fine.

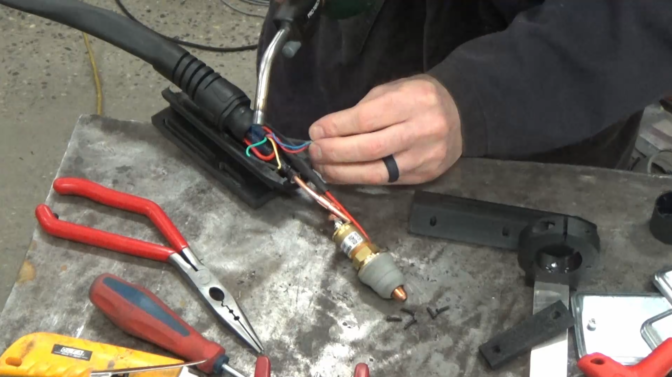

OMG - and you need this: 3D Print your hand torch to a machine torch