That looks nice!

Add to my to-do list.

3D printer

Photography by Tim Suddard

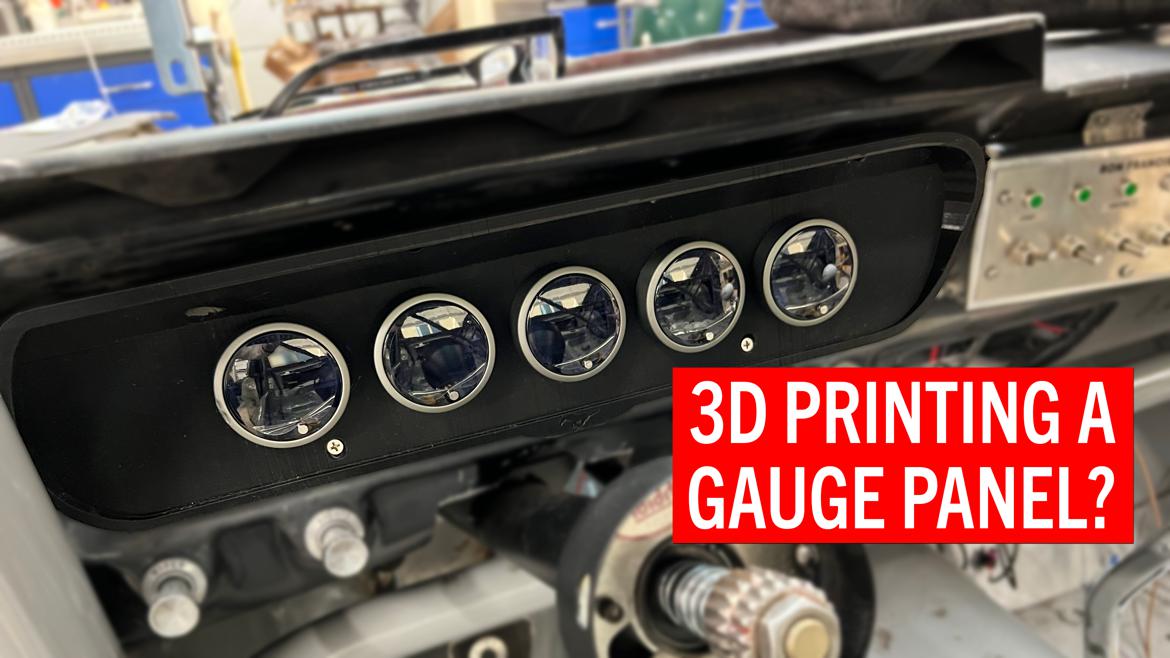

Our 1965 Mustang originally sported with a poorly made, flat aluminum panel fitted with repro Shelby-branded gauges. While the gauges were kind of cool, we wanted something that fit better and looked nicer.

While the market offers several custom gauge clusters for early Mustangs, they all have the typical five-gauge factory style setup: no tach and the speedometer front and center.

We didn’t need a speedometer in our race car, and we wanted an oversized tach right on the steering column where we could easily see it. We also wanted gauges for water temperature, oil temperature, oil pressure, volts and fuel level.

We’ve been making 3D parts in-house–check our Making Stuff series to drive deeper into that subject–and found a pattern for an early Mustang on the internet.

After downloading the pattern and modifying it for our five ProSport gauges, we first printed a low-res version in PLA+ to test fit. It worked as promised, so we then printed the final piece in the same material but with more walls and higher infill density.

I don't see any seams on that panel (I do see the Mustang emblem. Nice.) What printer are you guys using that you can get that all in one print?

I printed that with a Sainsmart INFI-20. It prints on a treadmill rather than a tradtional bed, so it's great for making a lot of parts or making one really long part like that dash.

In reply to Tom Suddard :

Nice. I wondered if it was one of those. Is it as awesome and easy to use as it seems, or does it have weird quirks you wouldn't think about?

Oh, no, it's horrible. I'm nearly a year in and just barely have it running reliably. They've sent new parts from China twice and I've completely redesigned the extruder.

That's a nice piece of work!

Since I don't produce a lot, don't have the patience to futz or the will to pay for great printing hardware I've been paying service providers. Xometry is expensive but fast and on-shore.

For flat panels I've used frontpanelexpress. Also pricey but they do great lettering and their color and coating selection is very good. If you don't have design tools their tool is decent and produces accurate paper printouts for testing.

Looks great! I usually do my final parts for race cars in ASA or Nylon. Carbon Nylon for stuff near the engine. PLA will soften up in the Florida sun. But it required some printer upgrades.

Here is a switch panel I recently finished. see

see

The panel looks nice and the gauges are a nice upgrade. I had not heard of these, but they looked like my Spec Pro tach I went to their website and they look pretty great.

The only complaint I have about the digital gauges I have used is they don't seem very durable (Speck Pro) and can be hard to read in some light. I have AutoMeter UltraLite analog gauges for everything but RPM because they just work so well. The programmability and features of the digital stuff is hard to pass up.

I'm loving this car and the build.

Displaying 1-8 of 8 commentsView all comments on the GRM forums

You'll need to log in to post.