The Camaro gets some flack around the office for having best-of-the-best stuff on it, but there's no arguing it's an awesome car.

II Much Fabrication built a bespoke stainless steel tank that houses a 2010 Camaro in-tank pump module. The crusty red filler cap and sender remain from the old tank. Some fool used our old tank as a jacking point while the car was out of our care.

The final pieces are test-fitted and ready for final welding. With such long, straight edges, the pieces should fit together perfectly.

Stainless steel is difficult to weld. John Parsons at II Much Fabrication makes it look easy and pretty.

The fabricated cross-brace mounting tabs locate the outrigger pickups.

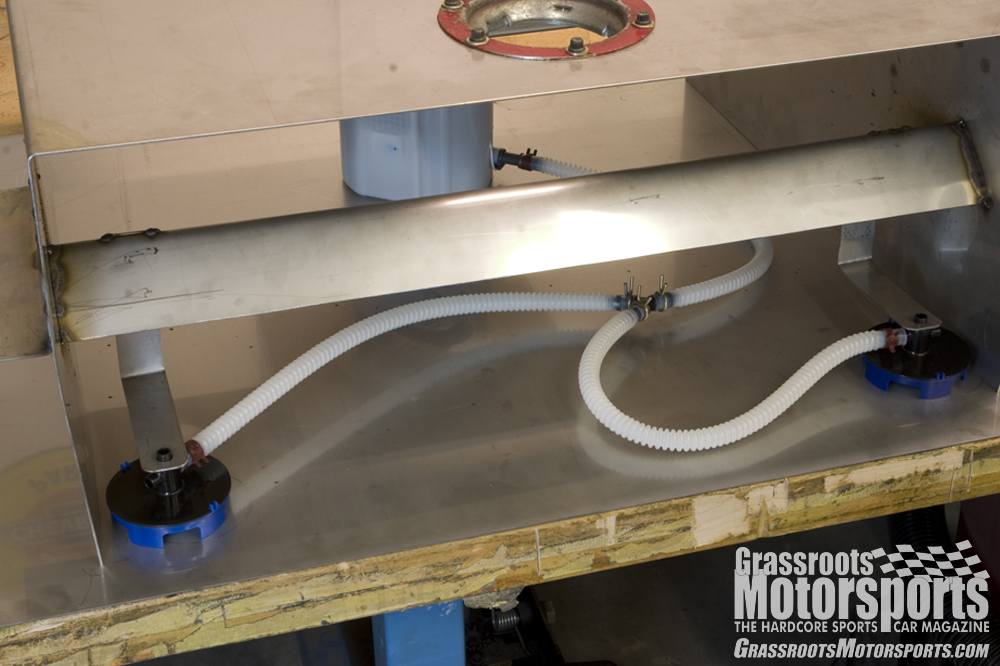

It's a shame that these fuel pick-ups are hidden from view. Plastic tubes connect the outrigger pick-ups to the pump module.

Here's how the remote fuel pickup assembly looks before it's entombed in stainless steel.

The giant pump module is mocked up for reference at this stage. Note that it's spring-loaded to always touch the tank bottom.

With the tank welded up, we turned our attention to the regulator swap. In stock form, a 2010 Camaro pump has too much pressure for our needs.

We replaced the 5th-gen Camaro regulator with a lower psi unit from a 4th-gen Camaro from RockAuto.com. The O-ringed nozzle on the left is from VaporWorx. It extends the return port deeper into the reservoir.

We're ready to immerse the pump module. All that remains is basic plumbing and wiring.

Around the GRM offices, the Camaro project takes a good bit of heat for its “best of everything” bespoke approach.

Caution: Fabrication and high-dollar content ahead!

Around the GRM offices, the Camaro project takes a good bit of heat for its “best of everything” bespoke approach. Hey, we can’t all drive Spec Miatas. Some of us get genuinely excited over the latest, greatest technology. If your head explodes at the sight of shiny new parts, click HERE. Otherwise, read on. While replacing a damaged custom fuel tank, we discovered a high-tech fuel pump solution based on OE-grade parts.

Armed with a 4x8-foot, $100 sheet of stainless steel, we reached out to our friend John Parsons at II Much Fabrication to bend, cut, and weld up something useful. We also picked John’s extremely large brain on two key subjects: Fuel starvation and pump life. In the high-revving world of track days, a shorted fuel supply might get you and your car rear-ended or induce catastrophic engine failure. Heat-related pump failure is a more common occurrence as enthusiasts increase engine output without factoring in fuel supply. As we intend to both drive this car in traffic and hit track days, we’re taking the Boy Scout approach: Be prepared. The time to engineer a proper fuel supply system is before that last stitch of weld lands on our new tank.

Is your significant other always forgetting to tank up your new truck? Don’t sweat it. Modern technology has all but eliminated fuel starvation and heat-related pump failure. The OE workaround is an in-tank pump module with a built-in reservoir, venturi pump and internal bypass regulator. It sounds complex, but everything is self-contained. That’s why they call it a module. To siphon every last drop of fuel, dual outrigger pickups pull fuel from the corners of the tank. Apparently, this design will allow you to autocross with only one gallon of fuel in the tank. The good news is that these fuel pump modules are readily available at any GM dealer or parts house for about $250. Silverado pickup trucks have used them since 2009. A Caddy CTS-V uses a module with two pumps, for example. And yes, these pumps are even starting to show up in junkyards. The bad news is that pump mounting is highly specific to the design. A small startup company called VaporWorx has developed a collection of fabricated parts that help you incorporate this technology into any custom tank of stainless steel design. If you’re curious about how these pump modules work or mount, the VaporWorx website is beyond comprehensive.

Before sealing up the tank, we had to swap out the pump module’s internal bypass regulator. Essentially a controlled leak within your fuel tank, a 2010 Camaro unit is set to bypass fuel at 88 psi. That’s way high for our needs. VaporWorx suggested that we switch to a 4th-gen Camaro regulator with a pressure bypass of roughly 58 psi. As an added benefit, the internal bypass design eliminates all return-line plumbing as well as the heated fuel that would be returned to the tank.

It’s a funny thing. We opened this chapter with a simple goal: Replace a damaged fuel tank. Instead, we ended up with a thoroughly engineered solution that should be good for 100,000 miles and 550 horsepower. Aside from the self-calibrating Holley ECM, we’d go so far as to say that this fuel pump module is the most technologically advanced part on the car. The tank and pump module turned out to be the missing link in our EFI swap. While this step slowed progress, the added reliability will save us time and grief down the line. Our headers are getting coated at Jet-Hot. That milestone is always light at the end of the tunnel for any major project. Meanwhile, we have some fuel system plumbing to tackle along with the installation of a very smart fuel tank vent and baffle system that every track day junkie will need. Please be sure to check back.

| Get topnotch sports car coverage regularly delivered to your mailbox. Subscribe now for tons of sports car content delivered throughout the year. |

View all comments on the GRM forums

You'll need to log in to post.