In this digital age, we’ve got LED and LCD readouts on practically everything we look at: stereos, microwaves, clocks, thermometers, dash displays and even hand tools. Dials and lights are seemingly a thing of the past, but these new gadgets can often complicate a job in their efforts to make it easier.

When it comes to solving electrical problems on our cars, a lot of people quickly turn to the digital multimeter. This handy little device will usually reveal the volts, ohms and other wonderful facts present in any of your car’s circuits. The trouble is, these things are often a bit complicated to use, clumsy and costly.

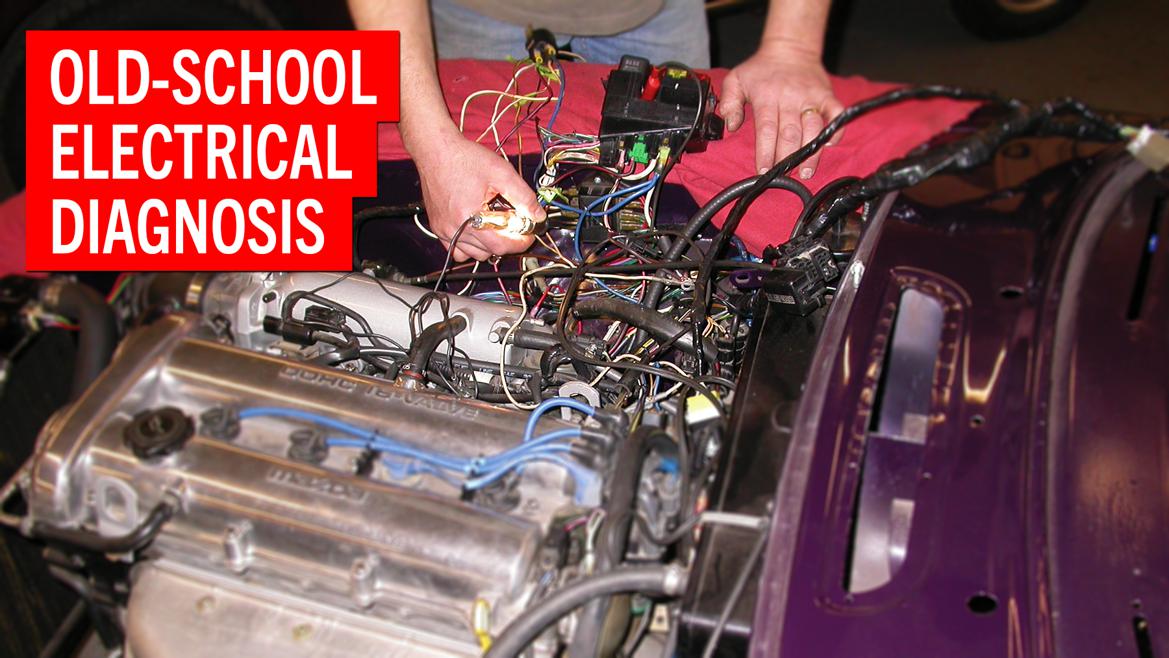

When we’re solving electrical problems, we usually go back to the basics with the ultimate digital tool: the test light. Just as digital components break information down into ones and zeroes, the test light looks at circuits in a digital manner: They are either on or off.

While it’s sometimes important to know the exact voltage or impedance of a circuit, most automotive electrical problems simply come from a lack of current flow. Find out where the current isn’t flowing—in other words, locate the broken circuit—and you’ve found the problem. The test light does this very well, all for a few bucks. Our favorite lights are compact, feature a bright light, and only have one lead and a sharp point.

There are some simple LED test lights that are very inexpensive or even come free with trailer wiring kits. Unfortunately, the LEDs only work in one polarity—with the clip attached to a ground and the sharp point at the power source. This type of test light is less helpful for troubleshooting, as it can’t be reversed to find a good ground source or work in a series.

We have two ways that we like to use our test lights. Usually, we ground the lead and use the point to search for power. Occasionally, we attach the lead to a power source and search for a good ground. The test light lets us solve just about every electrical problem out there.

One quick note: On computer-controlled cars, you’ll want to be careful when using a test light on the circuits and sensors that feed the computers. Some of these components can be damaged by heavier loads and sometimes the test light is too much. A digital multimeter is going to be your choice on these circuits.

Nonetheless, for older cars and more simple circuitry, here are some typical checks you can make with one of these bargain tools.

The easiest job for a test light is finding power. The alligator clip is attached to a good ground, while the probe is used to check for power. If the test light illuminates, you’ve got power.

A similar test can be done to look for a good ground. This time, the leads are reversed: The alligator clip is attached to a good positive power source, while the probe is then used to find a good ground. Instances such as this are where an old-school test light comes in handy, as small LED test lights only work when clipped to a ground.

If you have key-off battery drain, connect the test light in series with one of the battery posts. If the light glows, there’s a drain. Start disconnecting circuits until you find the one that turns off the light—there’s the problem.

If the problem is a slow-cranking engine and the battery and charging system seem okay, attach the alligator clip to a good ground on the body and touch the probe to a good ground on the engine. Then have an assistant crank the engine. If the light glows at all, the engine ground strap is bad, causing the slow cranking.

Wires don’t usually fail, but their connections often do. Use the test light to probe the terminal connectors.

If you can’t get to a wire’s terminals, it’s possible to pierce the insulation with the test light’s probe. Before considering the job finished, tape over or seal the hole you just made.

Comments

Good article.

My favorite feature of an old school incandescent test light is that it requires current to illuminate and is therefore a better indicator of a good circuit than a voltmeter or an LED test light. You can get a 12 volt reading on a voltmeter or light an LED through a pretty crappy connection but to light a test light you need a good one. More than once I've quickly found a connection problem in a lighting circuit using a test light that someone had spent hours trying to track down with a meter.

A test light is also the quickest way to test fuses in a fuse box. Turn on the key and the headlights and the light should illuminate when you touch the probe to each end of the fuse. No need to pull the fuses and look at them and because it's so quick to check them it's not even worth figuring out which fuse might cause the problem you're troubleshooting. Just check them all and if you find a bad one then confirm it's in a related circuit.

Next article: how to repair your burned out sensitive electronics from using our test light and poking the wrong bits

send me an email and you can get a real fuse center

Paul_VR6 (Forum Supporter) said:

Next article: how to repair your burned out sensitive electronics from using our test light and poking the wrong bits

Exactly, I watch for test lights in the shop and ask the techs what the heck they are using them on. Anything in our line of work can be tested by plugging in a computer and testing one of the 47 computers running the brains.

chandler said:

Paul_VR6 (Forum Supporter) said:

Next article: how to repair your burned out sensitive electronics from using our test light and poking the wrong bits

Exactly, I watch for test lights in the shop and ask the techs what the heck they are using them on. Anything in our line of work can be tested by plugging in a computer and testing one of the 47 computers running the brains.

One certainly should be aware of where they're poking a test light but if you know what you're doing they're often the best tool for the job.

APEowner said:

chandler said:

Paul_VR6 (Forum Supporter) said:

Next article: how to repair your burned out sensitive electronics from using our test light and poking the wrong bits

Exactly, I watch for test lights in the shop and ask the techs what the heck they are using them on. Anything in our line of work can be tested by plugging in a computer and testing one of the 47 computers running the brains.

One certainly should be aware of where they're poking a test light but if you know what you're doing they're often the best tool for the job.

I would say that a very high % of the time, the operator of such a tool does not have that knowledge.

I would say that a very high % of the time, the operator of such a tool does not have that knowledge.

Ok , I do not have the knowledge , please tell me what NOT to do....

newest car I have is. 2005 Chevy Express van ,

I doubt I can screw up my old air cooled VWs !

Thanks

Personally, the BEST thing that was in the article was warning people to be careful because of the computers. You kept the article simple, but most people don't really know much about electricity and they sure aren't going to learn by one small article.

The article was good, don't get me wrong, but with the little learning involved in it, I can foresee some, not all, will learn those lessons the hard way, and most of the computers in vehicles anymore are NOT cheap.

Displaying 1-8 of 8 commentsView all comments on the GRM forums

You'll need to log in to post.